Angular Position-Based Data Acquisition

A Precision Solution for Rotating Measurements

In many industrial applications, it is essential to synchronize analog measurements with the angular position of a rotating component. It is not enough to measure at regular time intervals; data must be captured at specific positions along a full rotation, even when the rotational speed varies.

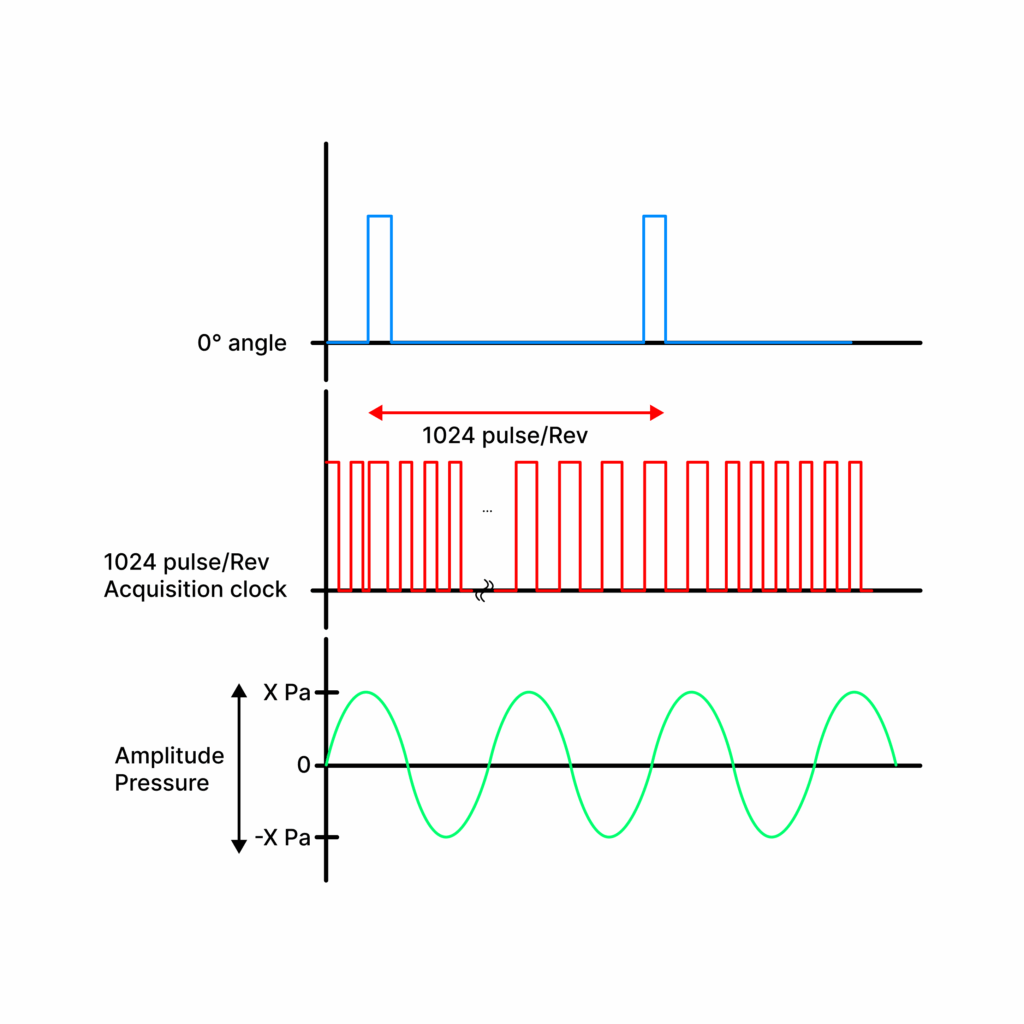

To meet this requirement, we developed a data acquisition system based on two primary signals. The first is a single pulse per revolution (1/Rev), which serves as the zero-angle reference. The second is a stream of 1024 evenly spaced pulses per revolution (1024/Rev), offering highly accurate angular markers, approximately every 0.35 degrees. An analog acquisition is triggered at each of these pulses.

This approach presents several technical challenges. First, the sampling frequency is not fixed; it changes depending on the rotational speed, which may fluctuate. Second, each measurement must be accurately timestamped despite these variations. And finally, it is often necessary to synchronize multiple acquisition channels across different boards without any temporal offset.

To overcome these constraints, we designed an architecture based on event-driven acquisition triggered by angular position. The 1024/Rev signal is used directly as an external clock for all acquisition boards, ensuring that each measurement aligns perfectly with a defined angular position. This guarantees consistent spatial sampling, regardless of rotation speed.

Task triggering is also tightly controlled. One board is designated as the master and is triggered by the 1/Rev signal. It then exports a start signal to the other boards, which are configured as slaves. As a result, all boards share the same reference start time (T₀) and remain fully synchronized throughout the acquisition process.

To provide accurate time references, a period counter measures the elapsed time between successive angular pulses. By accumulating these intervals from T₀ onward, it becomes possible to reconstruct a precise timeline aligned with each analog sample.

The resulting system allows for acquisition that is reliably triggered at fixed angular positions, with consistent timestamping even under variable-speed conditions. It also ensures full synchronization across multiple channels, making it an ideal solution for test benches and industrial environments where high-precision angular correlation is required.

Related Case Studies

Among our key projects:

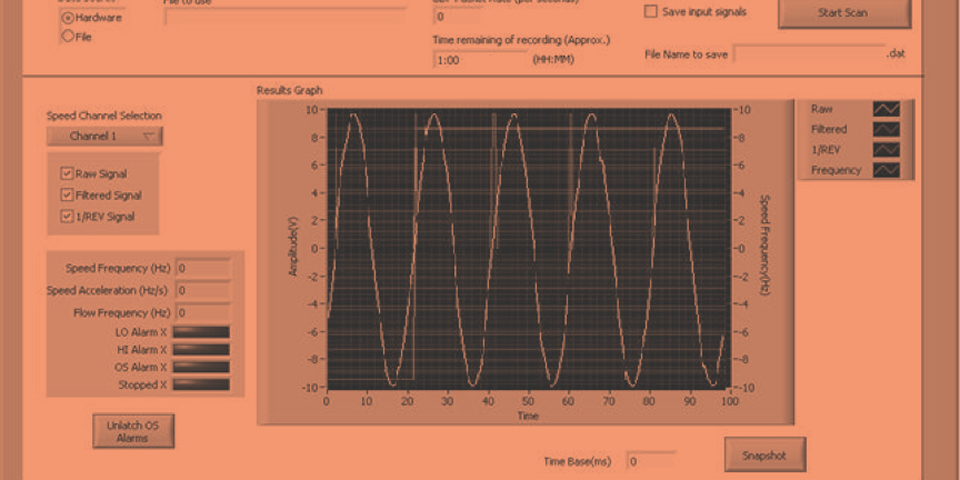

Frequency Processing System for Jet Engines

This project replaced an obsolete electronic board with a new frequency processing system for jet engines. Developed on an NI CompactRIO platform using LabVIEW Real-Time and FPGA, it ensures reliable signal acquisition, real-time analysis, and long-term system performance.

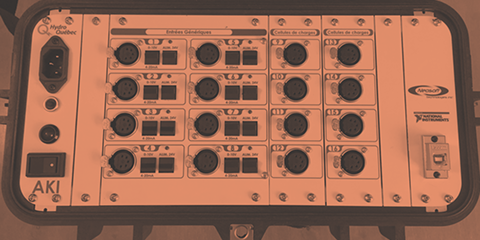

Portable Data Acquisition and Analysis System

Portable data acquisition and analysis system designed for field measurement.

The AKI System provides a complete and scalable solution to capture, visualize, and analyze multi-sensor data with precision and flexibility.

HIL Test Bench for Avionics Control Units (LRU)

Neosoft developed an HIL test bench to validate avionics control units (LRUs) in a real-time, deterministic environment.

This flexible and scalable solution provides synchronization, control, and monitoring through LabVIEW.

By choosing Neosoft for your custom software consulting and development needs, you benefit from recognized expertise, a personalized approach, and cutting-edge technologies to optimize your processes and ensure the quality of your products.

To discuss your specific needs, feel free to contact us.