Automated Cycling System for High-Power Batteries

Accurately Reproducing Extreme Conditions to Test Industrial Batteries

High-power energy storage systems, such as large-capacity lithium-ion batteries, require rigorous testing before integration into critical environments. To meet this need, we designed an automated cycling bench capable of simulating complex charge and discharge sequences, while integrating real-time monitoring of essential safety parameters.

Our client needed to automate testing procedures for various battery models while maintaining full oversight of their condition. The challenge: control dynamic and repeatable sequences, ensure seamless communication with the Battery Management System (BMS), and guarantee compatibility with different supervision and analysis tools.

A Flexible Software Platform Supporting a Robust Process

We developed a custom solution based on NI LabVIEW and TestStand environments. The software architecture, both modular and scalable, provides precise control over the entire testing process. It manages data exchange with the BMS through a dedicated communication bus, while simultaneously operating high-power cycling equipment.

Thanks to this approach, the client can simulate different usage profiles by accurately controlling the energy flow applied to the battery. The system continuously measures critical parameters such as cell temperature and state of charge and automatically generates detailed test reports for each cycle.

Synchronization, Performance, and Traceability

A key element of this solution is the ability to synchronize multiple data sources and devices in real time without compromising execution speed. The implemented system ensures fast and reliable data distribution to monitoring tools and analysis systems, with highly configurable options.

Each test produces a comprehensive log of all observed variables, allowing the engineering team to analyze battery behavior at every stage. These data are essential for documenting compliance with safety and performance standards.

A Scalable Solution Designed for Adaptability

The software environment provides great flexibility. It can be deployed across different test bench configurations without the need for extensive modifications. A simple configuration file is all it takes to adapt the solution to a new battery type or test equipment setup.

This adaptability significantly reduces the commissioning time for new benches while ensuring consistent reliability and test quality.

Results

Today, our client benefits from a comprehensive tool for validating high-power batteries. They gain precise test control, real-time performance monitoring, and full traceability for every cycle. This solution not only enhances the quality of the test process but also accelerates validation phases in demanding industrial environments.

Related Case Studies

Among our key projects:

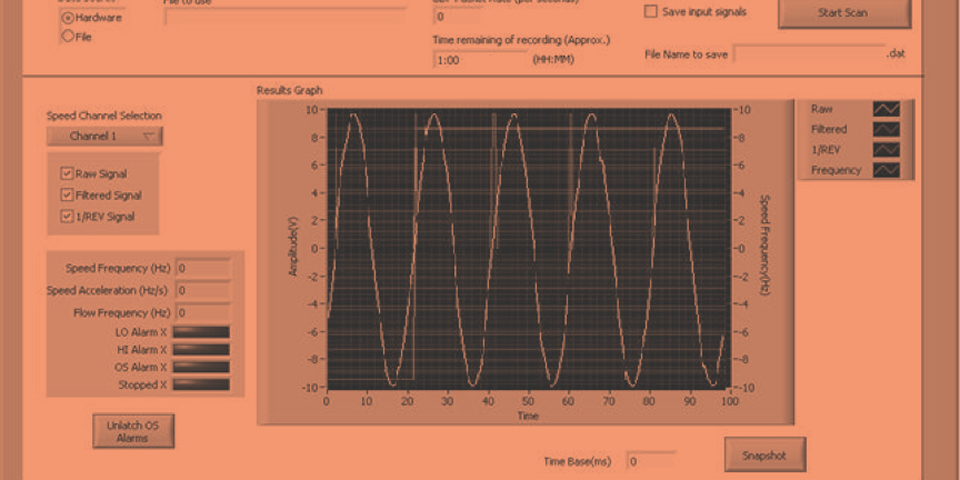

Frequency Processing System for Jet Engines

This project replaced an obsolete electronic board with a new frequency processing system for jet engines. Developed on an NI CompactRIO platform using LabVIEW Real-Time and FPGA, it ensures reliable signal acquisition, real-time analysis, and long-term system performance.

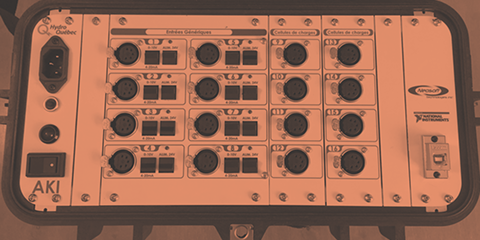

Portable Data Acquisition and Analysis System

Portable data acquisition and analysis system designed for field measurement.

The AKI System provides a complete and scalable solution to capture, visualize, and analyze multi-sensor data with precision and flexibility.

HIL Test Bench for Avionics Control Units (LRU)

Neosoft developed an HIL test bench to validate avionics control units (LRUs) in a real-time, deterministic environment.

This flexible and scalable solution provides synchronization, control, and monitoring through LabVIEW.

By choosing Neosoft for your custom software consulting and development needs, you benefit from recognized expertise, a personalized approach, and cutting-edge technologies to optimize your processes and ensure the quality of your products.

To discuss your specific needs, feel free to contact us.