Custom Climate Test Benches for Inverters

Development of Climate Test Benches for Inverters: A Custom Solution Built with LabVIEW

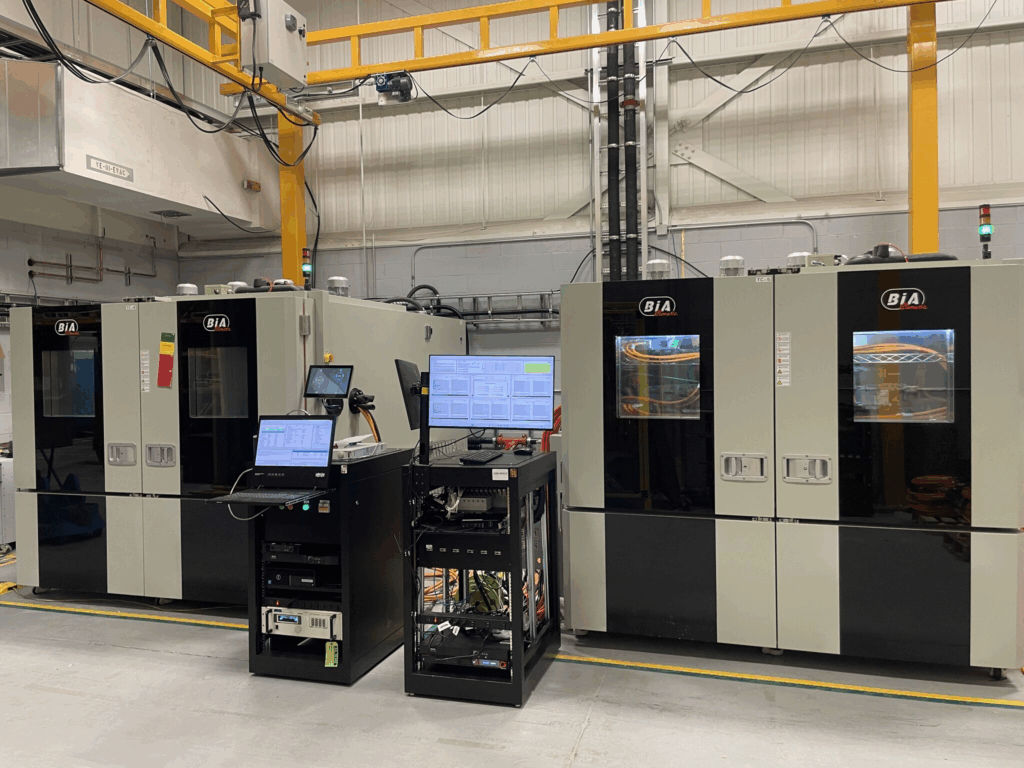

As part of a project aimed at validating inverters under extreme environmental conditions, a manufacturer in the electric drive technologies sector asked us to develop two fully customized test benches. The main objective was to expose these devices to controlled temperature and humidity stress. At the same time, current flow had to be regulated precisely using configurable test profiles. In addition, the solution needed to integrate smoothly into the existing production infrastructure. There were also strict requirements for data traceability.

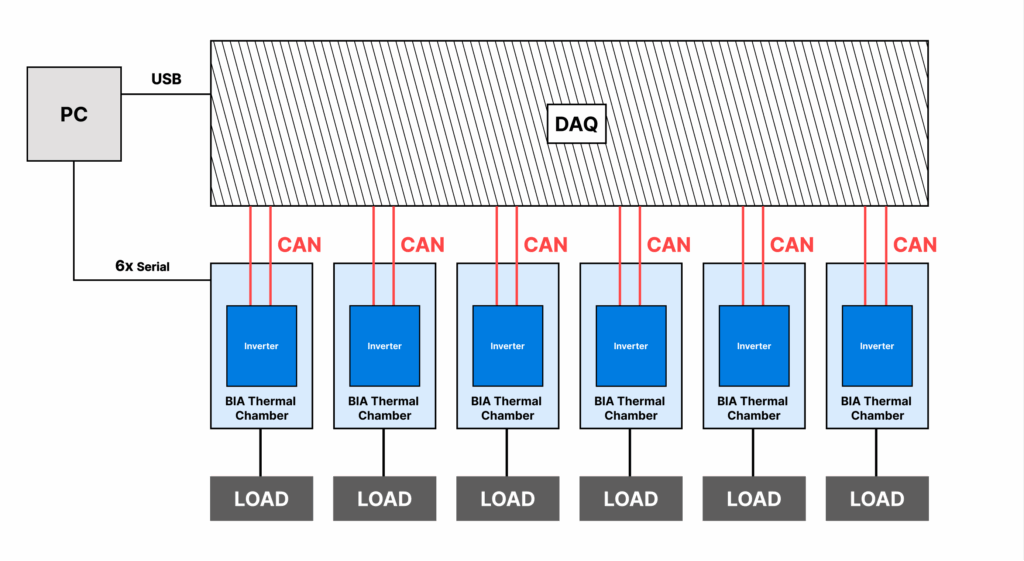

From the outset, several technical challenges appeared. Each test bench had to control multiple logical inverters simultaneously through XCP communication over CAN. Moreover, the system needed to support interchangeable thermal chambers without compromising data integrity or measurement stability. It also had to handle a wide variety of signals. For example, PT100 RTD temperature sensors, 4–20 mA analog inputs for flow sensors, and 24V valve control. Finally, the operator interface had to remain straightforward and consistent. A fixed resolution of 1920×1080 was required, ensuring usability in a production environment.

To meet these requirements, we created a custom software solution based on our standard LabVIEW framework. We then adapted it specifically to the project’s needs. This approach improved code robustness and reusability. Therefore, development could be completed within an efficient timeline. Communication with the inverters was implemented using NI-XNET modules compatible with the XCP protocol. Meanwhile, environmental data acquisition and actuator control were handled through NI CompactDAQ modules. As a result, all critical data was recorded in a locally hosted MS SQL Server database. This provided a reliable structure for post-test analysis and long-term traceability.

On the hardware side, each bench was built around an NI cDAQ-9179 chassis. This was connected via USB 3.0 to a dedicated workstation. Consequently, the setup offered both flexibility and scalability for future developments. The system also included multi-port CAN interfaces, analog input modules, and digital output modules for controlling system components.

Result

Final validation took place onsite at the client’s facility. A full Site Acceptance Test (SAT) confirmed the system’s reliability and compliance. Test cycles were performed on six physical inverters, representing twelve logical units. Afterwards, the client’s team continued with long-duration testing. They were confident in the system’s performance and long-term maintainability.

This project is another strong example of our ability to design tailor-made test solutions. Our systems combine mechanical, software, and industrial communication constraints. In addition, thanks to our expertise in software and electronic engineering, and our long-standing partnership with National Instruments, we deliver test systems that are robust, scalable, and built to last.

Related Case Studies

Among our key projects:

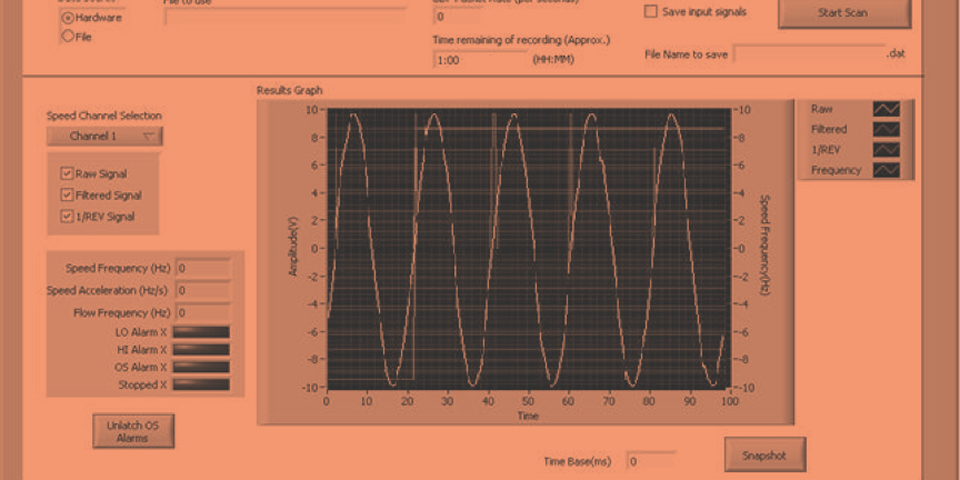

Frequency Processing System for Jet Engines

This project replaced an obsolete electronic board with a new frequency processing system for jet engines. Developed on an NI CompactRIO platform using LabVIEW Real-Time and FPGA, it ensures reliable signal acquisition, real-time analysis, and long-term system performance.

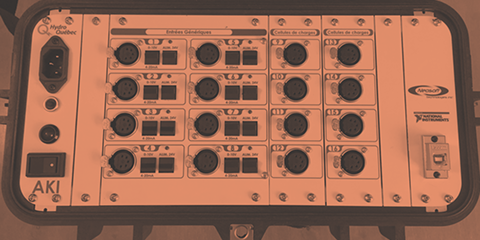

Portable Data Acquisition and Analysis System

Portable data acquisition and analysis system designed for field measurement.

The AKI System provides a complete and scalable solution to capture, visualize, and analyze multi-sensor data with precision and flexibility.

HIL Test Bench for Avionics Control Units (LRU)

Neosoft developed an HIL test bench to validate avionics control units (LRUs) in a real-time, deterministic environment.

This flexible and scalable solution provides synchronization, control, and monitoring through LabVIEW.

By choosing Neosoft for your custom software consulting and development needs, you benefit from recognized expertise, a personalized approach, and cutting-edge technologies to optimize your processes and ensure the quality of your products.

To discuss your specific needs, feel free to contact us.