Detection of Etching Cycles in Microfabrication

This project involves developing a real-time threshold violation detection system. It calculates the duration of each step in an etching cycle from a sampled signal. The software is adaptable to different micro-fabrication recipes and records the results for later analysis.

To build this system, we notably used LabVIEW software, which allowed us to develop it quickly and efficiently. With the multifunction acquisition multifunction from National Instruments and the DAQmx drivers, we were able to easily integrate a threshold violation detection algorithm. This enables the evaluation of the duration of various steps in the etching cycle of silicon wafers within the context of a micro-fabrication process.

Measurement

Algorithm

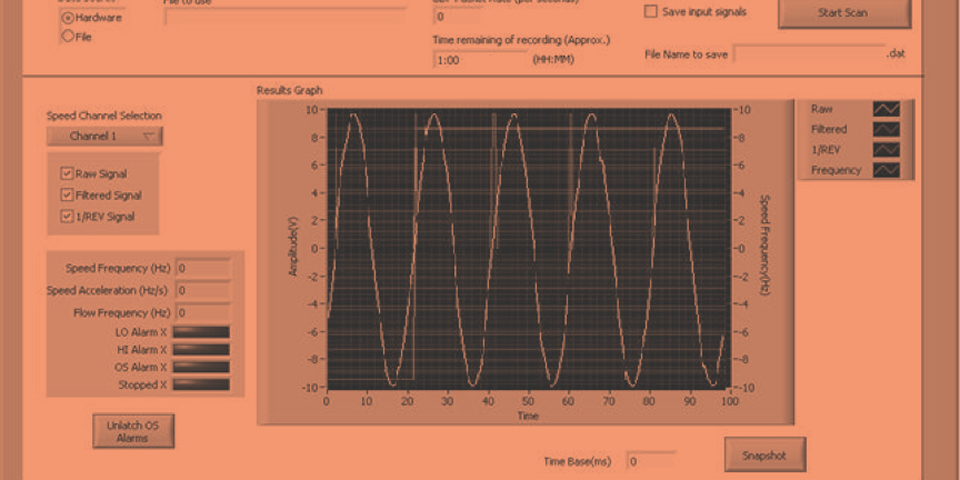

A threshold detection algorithm analyzes all the measurements collected in real-time. It also uses a user-defined threshold to detect the rise and fall of the electrical signal during etching. When an etching step begins, the electrical signal exceeds this threshold, allowing the step to be characterized. Once detected, the duration of the step is calculated and compared to the test limits to verify its compliance. The system displays the results of all detected steps on the user interface, organized for easy reading. Finally, it saves the data and results of the various etching cycles in log files in TDMS format.

The system then calculates the duration of each step and compares it to the test limits to verify compliance. It displays the results on the user interface in a clear and readable format. Finally, it also logs the data and results of each etching cycle in TDMS format log files.

Summary of results

The detection system also allows for recalling data from previously performed tests. It re-displays the voltage profile and the duration of the etching steps. The program retrieves the results from the cycle in the log files and then restarts the analysis to display everything on the user interface. This function makes it easier to view past results without the need for other software like Excel to visualize them.

In summary, the etching step detection application provided the client with an automated analysis option for their micro-fabrication process. The user interface allows them to visualize in real-time the progress of the etching of each silicon wafer, while automatically displaying the duration of the various detected steps. The program also offers the user the ability to maintain a history of performed etchings for future analysis. All of these features are consolidated into a single, simple, and easy-to-use interface, making the application very intuitive.

Related Case Studies

Among our key projects:

Frequency Processing System for Jet Engines

This project replaced an obsolete electronic board with a new frequency processing system for jet engines. Developed on an NI CompactRIO platform using LabVIEW Real-Time and FPGA, it ensures reliable signal acquisition, real-time analysis, and long-term system performance.

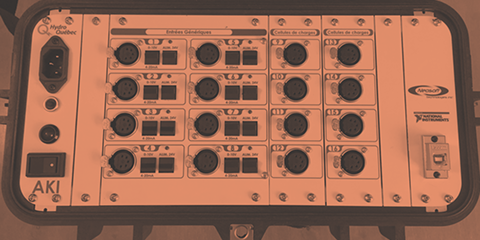

Portable Data Acquisition and Analysis System

Portable data acquisition and analysis system designed for field measurement.

The AKI System provides a complete and scalable solution to capture, visualize, and analyze multi-sensor data with precision and flexibility.

HIL Test Bench for Avionics Control Units (LRU)

Neosoft developed an HIL test bench to validate avionics control units (LRUs) in a real-time, deterministic environment.

This flexible and scalable solution provides synchronization, control, and monitoring through LabVIEW.

By choosing Neosoft for your consulting and custom software development needs, you benefit from recognized expertise, a personalized approach, and cutting-edge technologies to optimize your processes and ensure the quality of your products.

To discuss your specific needs, feel free to contact us.