HIL Test Bench for Avionics Control Units (LRU)

Challenge

The client needed a Hardware-in-the-Loop (HIL) test bench to validate avionics control units (LRUs) in a real-time, deterministic environment. The system had to interface a simulation environment and multiple control and monitoring software tools with several chassis, each equipped with a mix of I/O boards handling analog, digital, and discrete signals. The project involved several technical challenges. All chassis had to be precisely synchronized with one another while sustaining a high data throughput for distribution to multiple software applications. At the same time, the system had to record and monitor all variables in real time under strict timing constraints. Another key requirement was the ability to design a solution that was generic and adaptable to different test benches, regardless of the hardware used, while also being scalable for future evolutions.

For data redistribution across the control and monitoring applications, we implemented reflective memory boards installed in each chassis and in the simulation host computer. The software created a detailed memory mapping that assigned dedicated spaces and addresses to each variable described in the configuration file. The I/O management engines were connected to a central engine, which handled both reading and writing operations, guaranteeing smooth and synchronized data flow across the entire system.

In addition, we developed a host application in LabVIEW using the Actor Framework. This host software allowed remote operation of the embedded system while remaining flexible to the client’s evolving needs. Command communication was implemented over TCP, while real-time monitoring of variables used UDP. This modular framework ensures that new monitoring or control tools can be added in the future with minimal effort. To further simplify integration, we also created a configuration file translator capable of processing thousands of variables, which automated the setup of each test bench.

Solution

To address these requirements, we developed a hardware and software architecture entirely programmed in LabVIEW. Synchronization between chassis was achieved by integrating timing boards that shared a common clock. Upon startup, the software automatically configured synchronization according to parameters defined in a configuration file, allowing the system to adapt seamlessly to different hardware setups. Data management was structured around independent engines, each dedicated to handling a specific type of signal, ensuring reliable data rates and modularity.

Results

The final solution delivered a robust, flexible, and scalable HIL test bench. The client now has a system capable of controlling and monitoring a wide variety of heterogeneous signals while maintaining high-frequency data rates. Setting up a new test bench no longer requires custom software development, only the creation of a configuration file describing the necessary variables. This approach significantly reduces both integration time and costs, while enhancing reliability and reusability across projects. The architecture also enables centralized control of multiple test benches from a single host or, alternatively, distributed operation across multiple hosts and locations. The client ultimately benefits from a powerful, future-proof solution that streamlines the functional validation of avionics control units and adapts to the evolving demands of modern aerospace programs.

Related Case Studies

Among our key projects:

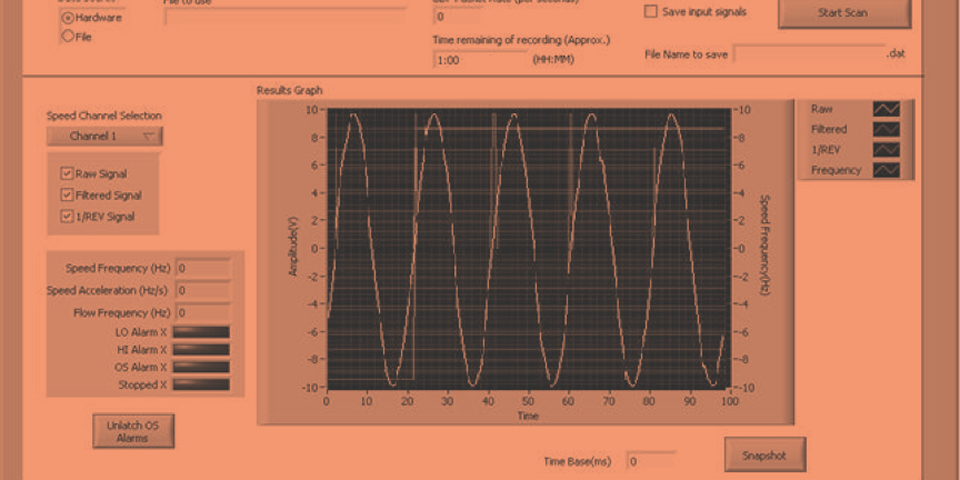

Frequency Processing System for Jet Engines

This project replaced an obsolete electronic board with a new frequency processing system for jet engines. Developed on an NI CompactRIO platform using LabVIEW Real-Time and FPGA, it ensures reliable signal acquisition, real-time analysis, and long-term system performance.

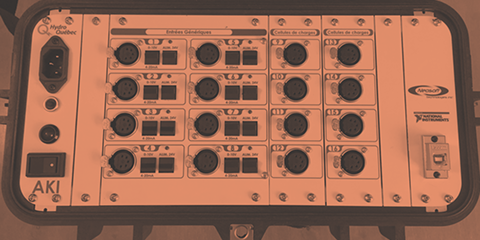

Portable Data Acquisition and Analysis System

Portable data acquisition and analysis system designed for field measurement.

The AKI System provides a complete and scalable solution to capture, visualize, and analyze multi-sensor data with precision and flexibility.

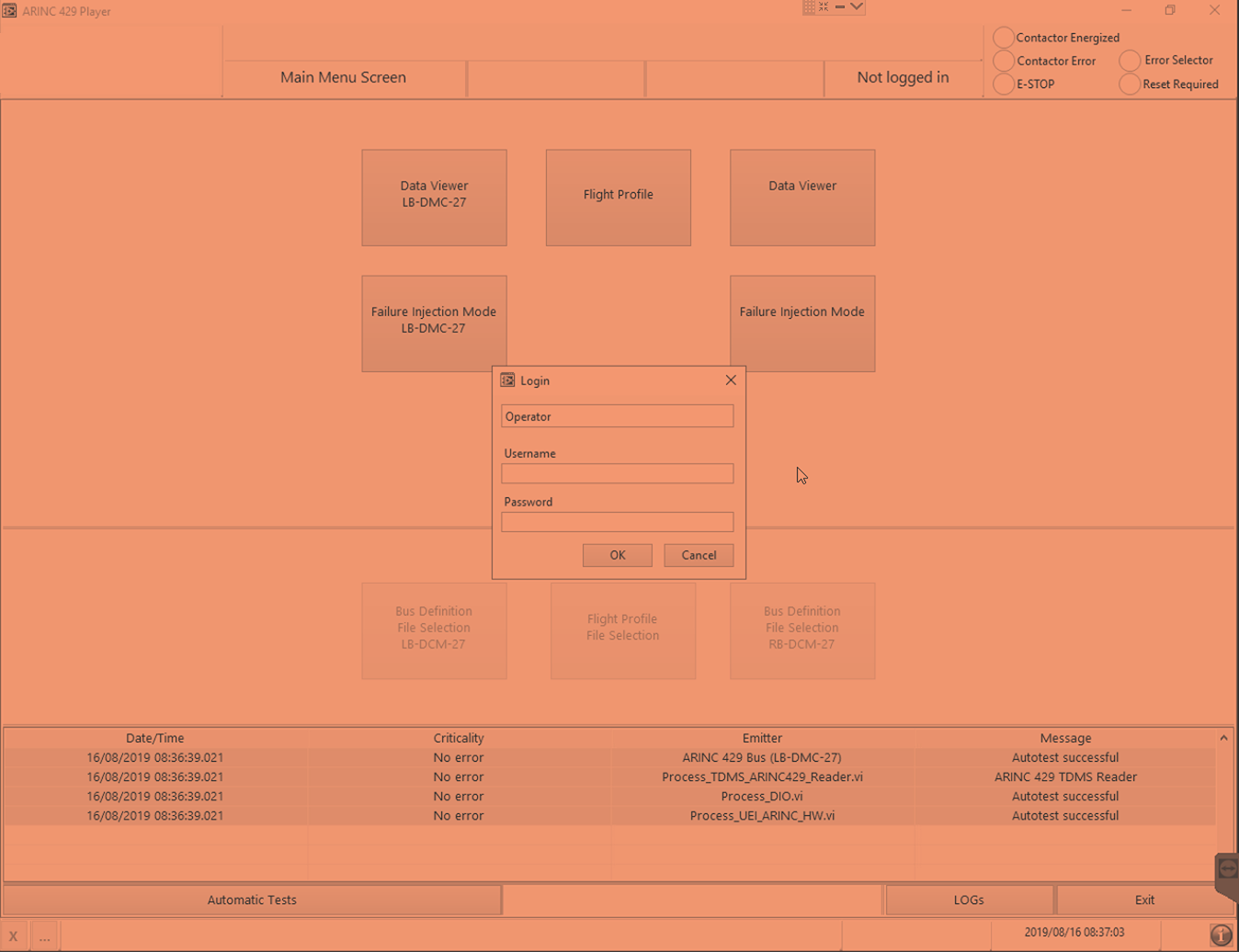

ARINC-429 Data Record and Playback System

ARINC-429 record and playback system that accurately captures and replays avionics data streams with precise time synchronization.

Includes fault injection and an intuitive LabVIEW interface to test, visualize, and validate onboard communications.

By choosing Neosoft for your custom software consulting and development needs, you benefit from recognized expertise, a personalized approach, and cutting-edge technologies to optimize your processes and ensure the quality of your products.

To discuss your specific needs, feel free to contact us.