Recent advances in processors and camera technologies have significantly expanded the potential of machine vision.

At Neosoft Technologies, we offer tailored industrial vision solutions to meet your specific needs—whether it’s shape recognition, precision measurements, product alignment, part counting, or defect detection. Integrating machine vision systems into your processes allows you to significantly improve the quality and consistency of your products.

Industrial Vision

Industrial Vision Solutions

Our Machine Vision Systems

Our machine vision systems are designed to automate inspection and quality control tasks. Through real-time visual inspection, anomalies and defects can be detected immediately, ensuring production compliance with the highest standards. This approach minimizes human error and improves operational efficiency.

When traditional algorithms are insufficient, we can train artificial intelligence (AI) models to meet complex analysis requirements

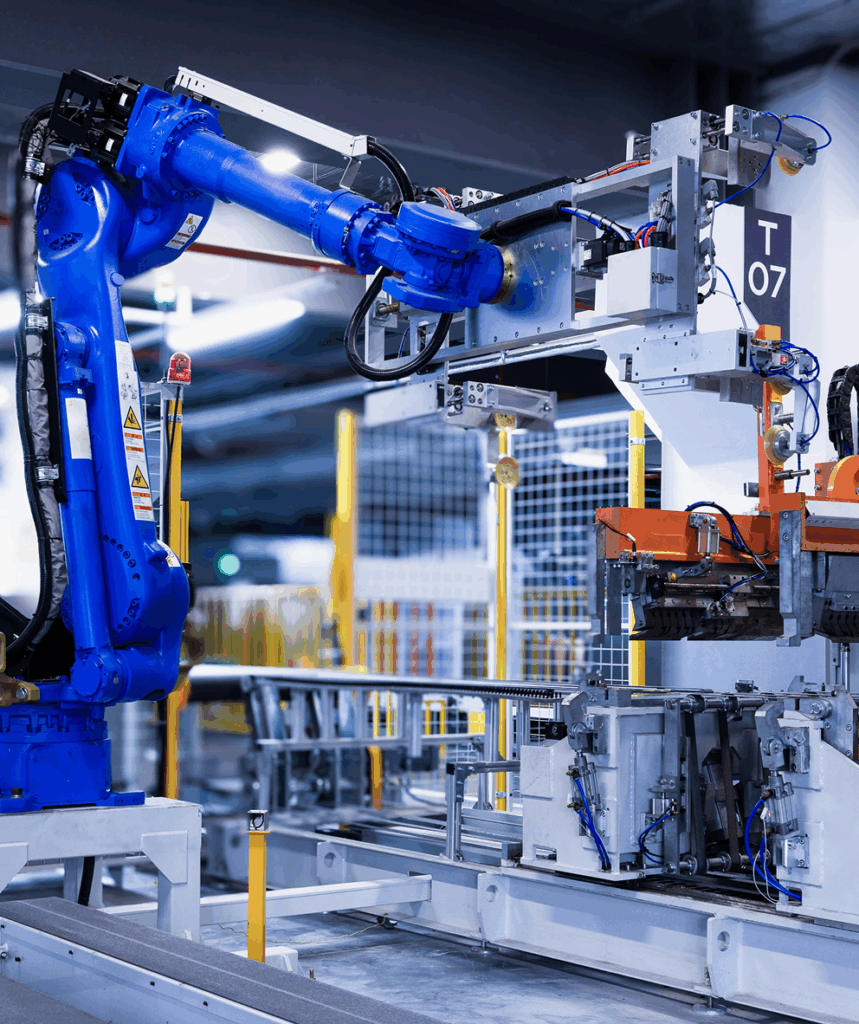

Image Analysis and Robotic Vision

Industrial image processing combined with robotic vision opens the door to advanced automation. Equipping robots with vision systems allows them to perform complex tasks with increased precision. Such as sorting, assembling, or dimensional control. This synergy between vision and robotics enhances production efficiency and reduces associated costs.

FAQ - Industrial Vision

Industrial vision is a technology that uses cameras and software to visually analyze industrial objects and processes in real time.

It improves quality, productivity, traceability, and enables automation of inspections and controls on production lines.

Industrial vision is used in automotive, food processing, electronics, pharmaceuticals, and logistics, among others.

Integration is done through needs analysis, choosing suitable equipment, software development, and on-site commissioning.

2D, 3D, infrared, and multispectral cameras are used depending on specific inspection and analysis needs.

Related Case Studies

Among our key projects:

Textile Misalignment Detection using AI

Optimize textile production with our artificial vision solution for continuous misalignment detection.

Optical Fiber Inspection

Ensure the quality and performance of your optical fibers with our advanced automated inspection solutions.

Automated Alignment System – Fine Guidance Sensor

Neosoft develops an automated alignment system for Fine Guidance Sensors (FGS), providing precision and performance for advanced optical applications.

By choosing Neosoft for your custom software development and consulting needs, you benefit from proven expertise, a personalized approach, and cutting-edge technologies to streamline your processes and ensure product quality.

Let’s discuss your project!