Optical Fiber Inspection

Optical Fiber Defect Detection via Robotic Vision

This automated inspection project aimed to detect defects in optical fibers right after their creation. To achieve this, two cameras continuously and in real-time inspected the fiber as it exited the stretching tower. The application specifically measured the concentricity percentage of the cladding and coating to identify potential errors.

The system was based on LabVIEW software, paired with the NI Vision Development Module. It captured several images per second and analyzed each frame to detect possible defects. Finally, the inspection was carried out according to the parameters configured by the operator.

The system also records each detected error in a file and marks the fiber by spraying red paint on it. This allows the operator to examine each defect individually and remove the faulty fiber if necessary. Additionally, the system collects statistics for each inspection, which are particularly useful for identifying potential issues related to the fiber formation tower used in the manufacturing process.

Related Case Studies

Among our key projects:

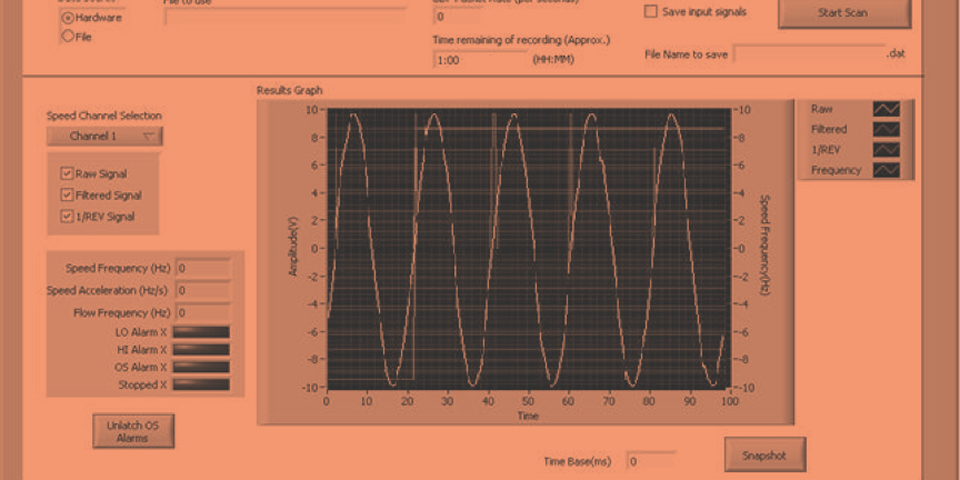

Frequency Processing System for Jet Engines

This project replaced an obsolete electronic board with a new frequency processing system for jet engines. Developed on an NI CompactRIO platform using LabVIEW Real-Time and FPGA, it ensures reliable signal acquisition, real-time analysis, and long-term system performance.

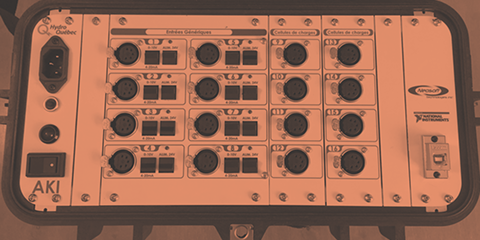

Portable Data Acquisition and Analysis System

Portable data acquisition and analysis system designed for field measurement.

The AKI System provides a complete and scalable solution to capture, visualize, and analyze multi-sensor data with precision and flexibility.

HIL Test Bench for Avionics Control Units (LRU)

Neosoft developed an HIL test bench to validate avionics control units (LRUs) in a real-time, deterministic environment.

This flexible and scalable solution provides synchronization, control, and monitoring through LabVIEW.

By choosing Neosoft for your custom software development and consulting needs, you benefit from recognized expertise, a personalized approach, and cutting-edge technologies to optimize your processes and ensure the quality of your products.

To discuss your specific needs, feel free to contact us.