Smart Battery Cycling Solution

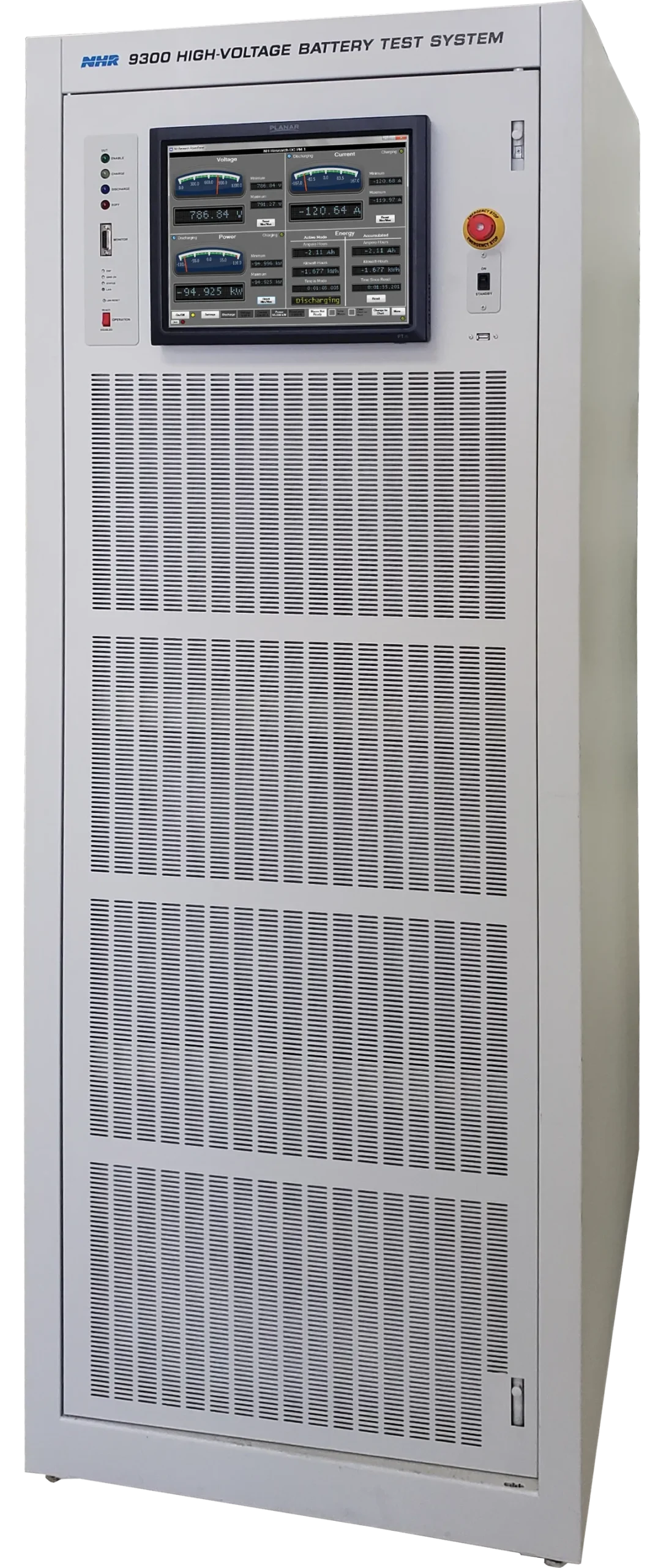

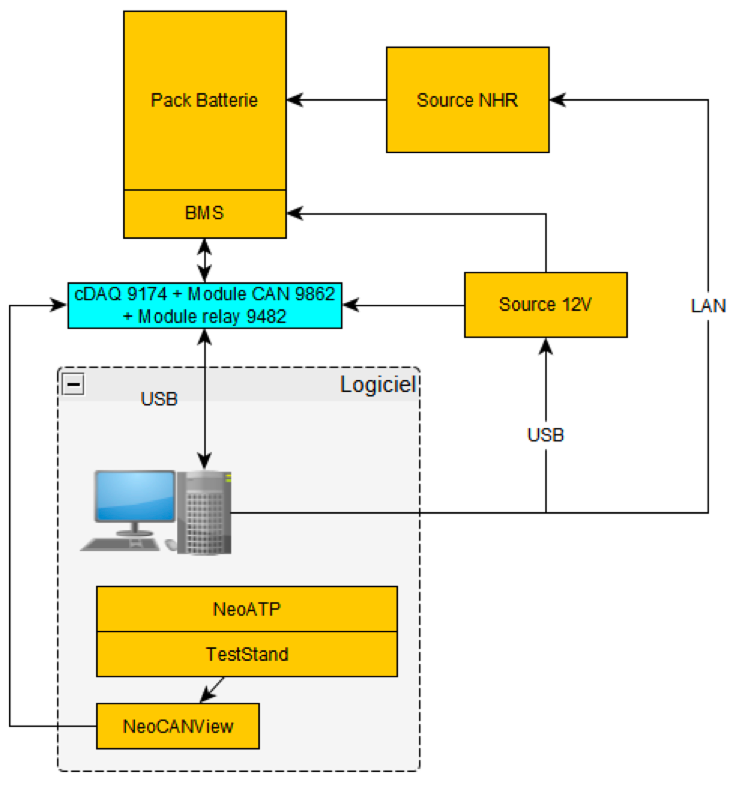

To validate the performance of high-power lithium-ion battery packs, we developed a fully automated test bench. It is built around the 9300 Series High-Voltage Battery Test System from NH Research. This system runs complex charge and discharge cycles with high precision. At the same time, it communicates in real time with the Battery Management System (BMS) via the CAN bus.

We use LabVIEW and NI TestStand to control the entire process. These tools ensure reliable, repeatable, and fully automated test sequences.

At the heart of the setup is the NH 9300, a modular, regenerative high-voltage test system. The 9300 Series easily adapts to different power levels, up to 224 kW. We connect it via LAN to a control PC, which sends commands through custom LabVIEW drivers developed specifically for this application.

Our test profiles typically include charging from 50% to 100% State of Charge (SoC), a full discharge to 0%, and then a partial recharge to 30%. The NHR 9300 Series executes these steps at a nominal current close to 1C. During the entire process, we monitor cell temperatures, pack voltages, and BMS alerts in real time.

A NI‑9862 CAN interface handles communication with the BMS. We use NeoCANView to decode CAN messages. This software also lets us send commands and requests directly to the BMS.

For the operators, we’ve used our product NeoATP as a standard operator interface built for automated test. It allows technicians to launch and monitor test sequences easily. Using a barcode scanner, the system can identify the unit under test and load the correct test profile automatically. A LabVIEW API links NeoCANView, NeoATP, and TestStand to ensure smooth coordination between all software components.

We log all measurements in time-stamped TDMS files. This ensures accurate and complete data traceability. Every second, we poll the NHR 9300 Series High-Voltage Battery Test System to track current draw. We then integrate this data to calculate the ampere-hour capacity delivered during each phase.

After each test cycle, TestStand automatically generates a report. Reports are available in HTML, XML, ATML, or ASCII format. They include start and end SoC values, min/avg/max voltages and temperatures, and any safety flags triggered by the BMS that we identified with the customer.

This solution combines proven technologies. The NHR 9300 Series handles charge and discharge of the battery. The CAN bus manages communication with the BMS. And the software tools. LabVIEW, TestStand, NeoCANView, and NeoATP, ensure complete automation, supervision, and control of the test sequence.

We built a robust, scalable test environment, tailored for high-voltage battery systems. Leveraging the modular software architecture and the NHR 9300 Series, which is compatible with the NHR 9200 Series, we can support a wide range of industrial applications, from electric vehicles to renewable energy storage and aerospace systems.

The NHR 9300 also provides a major advantage: it can return energy to the grid. This regenerative capability increases energy efficiency and reduces operating costs.

To learn more about the NHR 9300 Series High-Voltage Battery Test System, visit the product page from their distributor, Testforce:

👉 https://www.testforce.com/brands/nh-research/battery-test-emulation/9300-series-high-voltage-battery-test-system.html

This project shows our ability to integrate advanced technologies into a streamlined, high-performance solution designed to meet the toughest demands of High-Voltage Battery automated testing.

Related Case Studies

Among our key projects:

Frequency Processing System for Jet Engines

This project replaced an obsolete electronic board with a new frequency processing system for jet engines. Developed on an NI CompactRIO platform using LabVIEW Real-Time and FPGA, it ensures reliable signal acquisition, real-time analysis, and long-term system performance.

Portable Data Acquisition and Analysis System

Portable data acquisition and analysis system designed for field measurement.

The AKI System provides a complete and scalable solution to capture, visualize, and analyze multi-sensor data with precision and flexibility.

HIL Test Bench for Avionics Control Units (LRU)

Neosoft developed an HIL test bench to validate avionics control units (LRUs) in a real-time, deterministic environment.

This flexible and scalable solution provides synchronization, control, and monitoring through LabVIEW.

By choosing Neosoft for your custom software consulting and development needs, you benefit from recognized expertise, a personalized approach, and cutting-edge technologies to optimize your processes and ensure the quality of your products.

To discuss your specific needs, feel free to contact us.