Textile Misalignment Detection using AI

This project aims to identify misalignments of textile strips during the production of textile products. To achieve this, the system quickly captures images of the fibers and analyzes these images to check their conformity based on configurable parameters.

Since the assembly line operates at a very high speed (several hundred meters per minute), the detection algorithm must run sixty times per second. The system then sends the results to the programmable logic controller (PLC) that controls the assembly line via Modbus communication over TCP/IP.

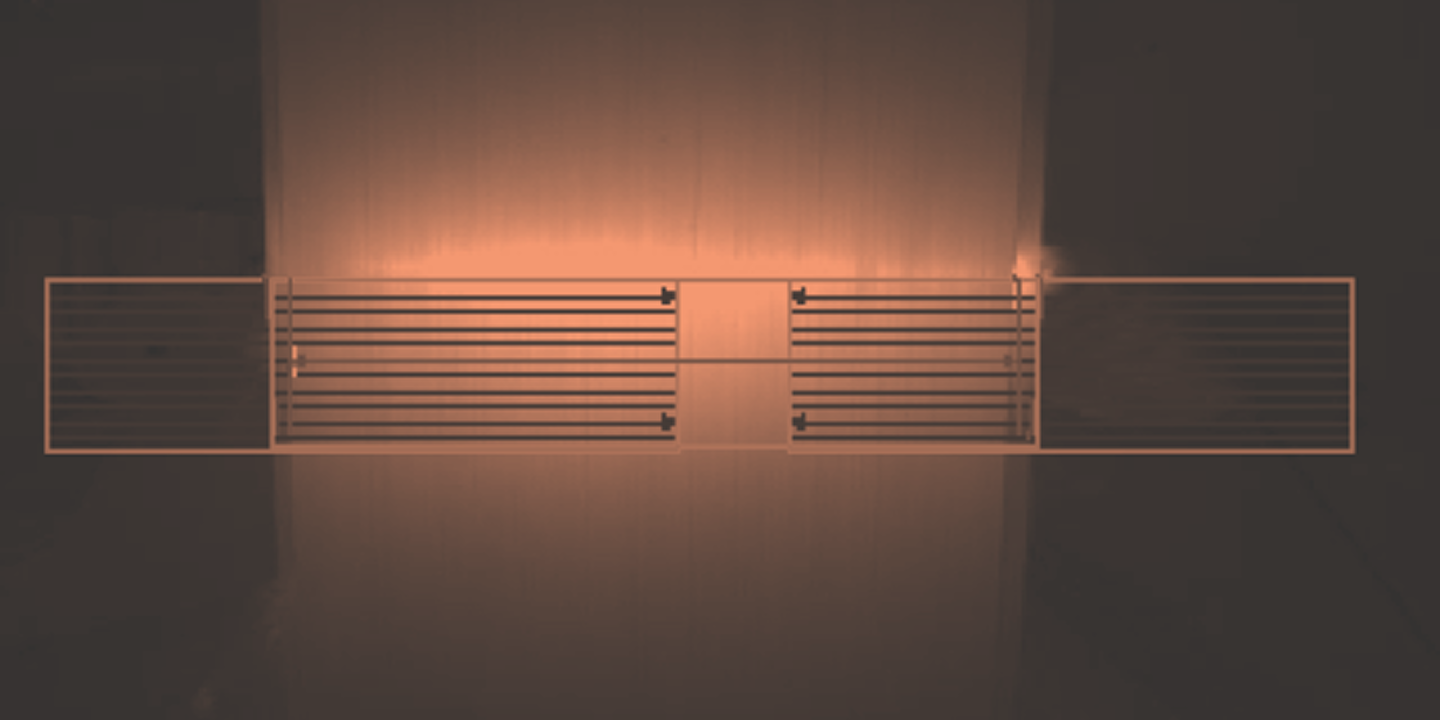

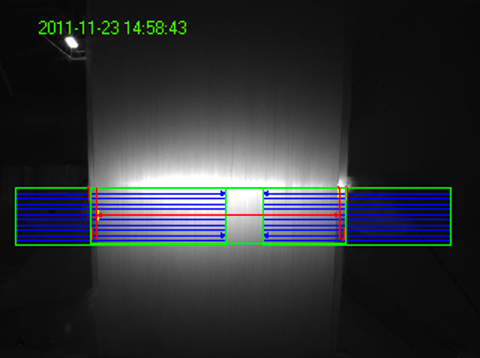

Figure 1 shows a typical image that the system must analyze. In this image, two strips of textile are visible. The system then evaluates the percentage of misalignment of the fibers relative to each other. To accelerate image processing, the region of interest (ROI) is determined based on the darkest part of the image.

The vision algorithms are executed on a National Instruments smart camera capable of running real-time code. The advantage of this feature is that the camera does not require a startup or shutdown sequence. In fact, to operate the camera and its detection algorithm, all that is needed is to plug it into a standard electrical outlet.

The system also provided a visual interface deployed from the camera, accessible via TCP/IP communication. Additionally, this interface allowed users to view the image captured by the camera.

Thus, if the strips are misaligned by a percentage exceeding a configurable threshold, an alarm is triggered to alert the operator. Communication with a programmable logic controller (PLC) via Modbus is then carried out to stop the assembly line if the misalignment exceeds a certain limit.

Related Case Studies

Among our key projects:

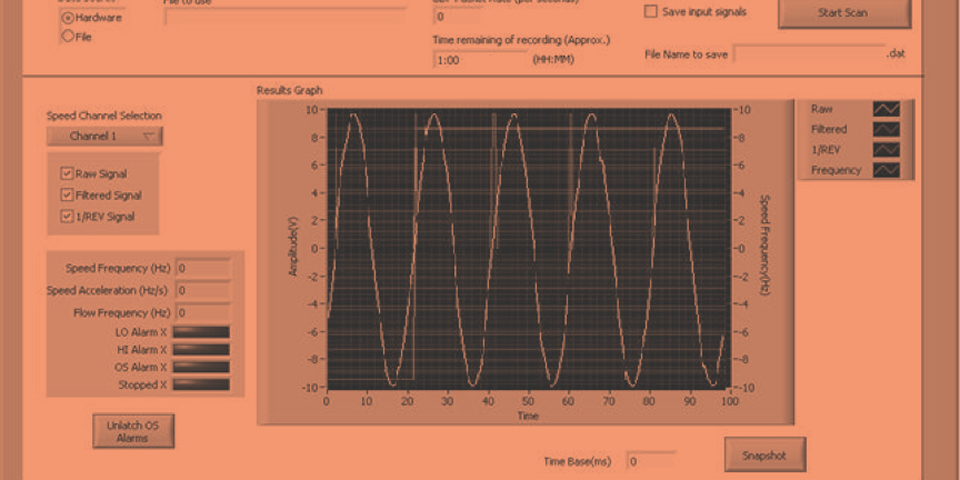

Frequency Processing System for Jet Engines

This project replaced an obsolete electronic board with a new frequency processing system for jet engines. Developed on an NI CompactRIO platform using LabVIEW Real-Time and FPGA, it ensures reliable signal acquisition, real-time analysis, and long-term system performance.

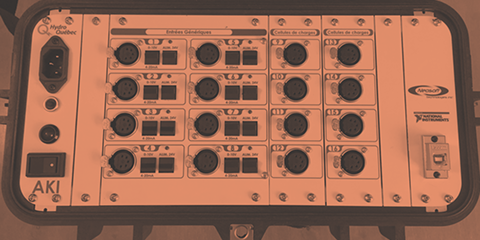

Portable Data Acquisition and Analysis System

Portable data acquisition and analysis system designed for field measurement.

The AKI System provides a complete and scalable solution to capture, visualize, and analyze multi-sensor data with precision and flexibility.

HIL Test Bench for Avionics Control Units (LRU)

Neosoft developed an HIL test bench to validate avionics control units (LRUs) in a real-time, deterministic environment.

This flexible and scalable solution provides synchronization, control, and monitoring through LabVIEW.

By choosing Neosoft for your custom software consulting and development needs, you benefit from recognized expertise, a personalized approach, and cutting-edge technologies to optimize your processes and ensure the quality of your products.

To discuss your specific needs, feel free to contact us.