Frequency Processing System for Jet Engines

The challenge

The purpose of this project was to develop a system capable of computing and analyzing signals coming from various sensors installed on an aircraft jet engine. These signals, originating from speed, flow, and position sensors, were processed to extract key information and determine the corresponding frequency values.

This project was also part of a broader modernization effort aimed at replacing an obsolete processing board that was no longer supported by the manufacturer. The challenge was to design a new frequency processing system that could replicate the behavior of the legacy hardware while improving long-term reliability and ensuring full compatibility with the client’s existing environment.

The turbine engine sensors generated highly noisy analog signals that required complex filtering and real-time analysis. The original processing board, which had become obsolete, could no longer meet operational or maintenance requirements. It was therefore necessary to replace it with a robust and sustainable solution capable of reproducing the previous functionality while introducing improved processing capabilities and an open software architecture.

The new system also had to allow secure remote access and autonomous operation over extended periods without manual intervention. Ensuring functional continuity during the transition from the legacy hardware to the new platform was a key requirement.

Developed Solution

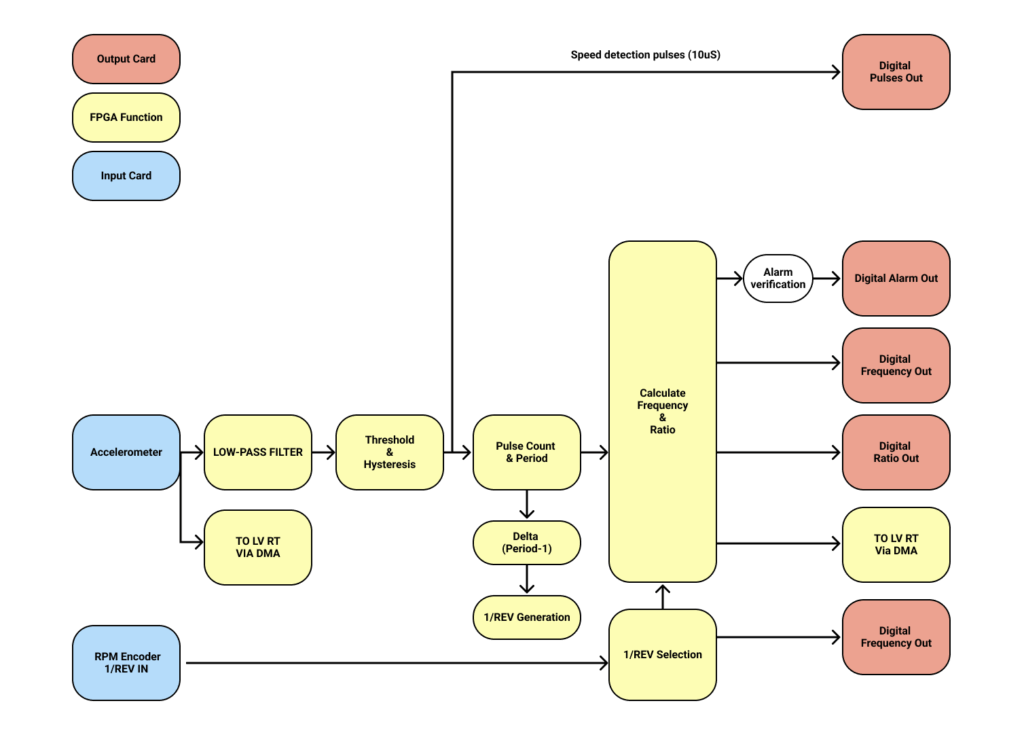

The system was entirely redeveloped on a NI CompactRIO platform running NI Real-Time. This architecture provided a reliable and deterministic execution environment while making the system easier to maintain and upgrade in the future. Development was carried out using LabVIEW Real-Time and LabVIEW FPGA, tools ideally suited for high-speed signal processing and real-time algorithm execution.

A web-based interface was implemented to allow system configuration and control from any computer connected to the local network. Access is secured by user credentials, and both raw and processed signals can be visualized directly through a standard web browser without additional software installation.

In addition to the web interface, a TCP/IP communication interface was developed to enable remote control and data exchange with third-party applications. Commands can be sent to the system, and computed results are periodically transmitted in the requested format and at the configured rate, ensuring seamless integration with existing test or monitoring infrastructures.

Through this redesign, the obsolescence of the original board was fully addressed. The new system replicates all of its original functionalities while delivering superior performance, higher stability, and a flexible software-based framework. Being a standalone device running on CompactRIO, the system can be powered on or off simply by plugging or unplugging it from a standard 120V AC source, which greatly simplifies daily operation.

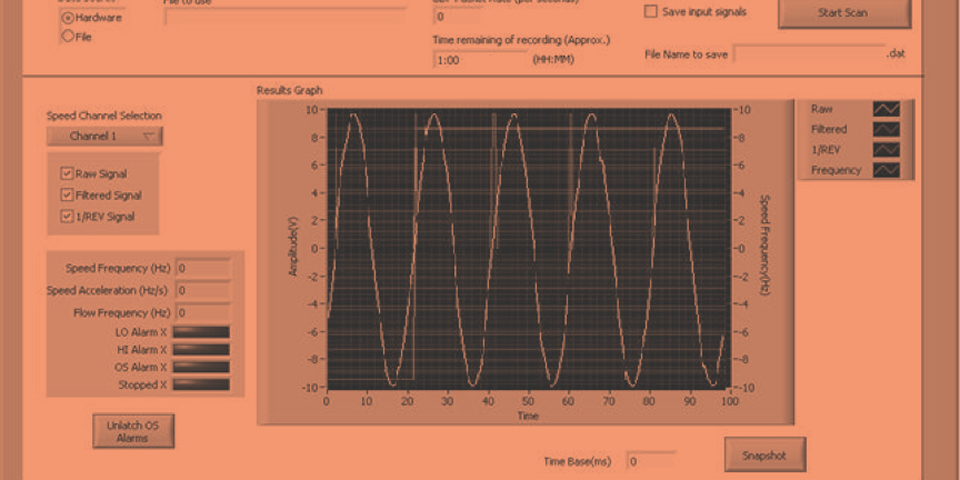

Figure 3 – Typical Turbine Engine Signal

Results

All project objectives were successfully achieved. The client now benefits from a modern, reliable, and high-performance frequency processing system that not only replaces but surpasses the legacy hardware. The new solution provides greater stability, improved signal accuracy, and simplified maintenance procedures.

By migrating to a CompactRIO platform, the risks associated with hardware obsolescence have been completely eliminated, ensuring long-term system continuity and reduced downtime. The collaboration with National Instruments was instrumental in overcoming the FPGA resource limitations encountered during development, resulting in a robust and future-proof system.

The main challenge involved managing limited FPGA resources, which required optimizing and re-architecting portions of the code to achieve the required performance. This experience strengthened our expertise in upgrading obsolete hardware systems to CompactRIO-based architectures, ensuring functional continuity, scalability, and reliability in demanding operational environments. The lessons learned from this project will guide future modernization efforts involving legacy systems and FPGA-based designs.

Related Case Studies

Among our key projects:

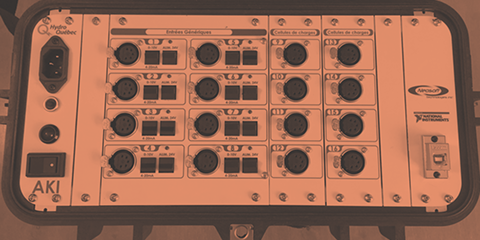

Portable Data Acquisition and Analysis System

Portable data acquisition and analysis system designed for field measurement.

The AKI System provides a complete and scalable solution to capture, visualize, and analyze multi-sensor data with precision and flexibility.

HIL Test Bench for Avionics Control Units (LRU)

Neosoft developed an HIL test bench to validate avionics control units (LRUs) in a real-time, deterministic environment.

This flexible and scalable solution provides synchronization, control, and monitoring through LabVIEW.

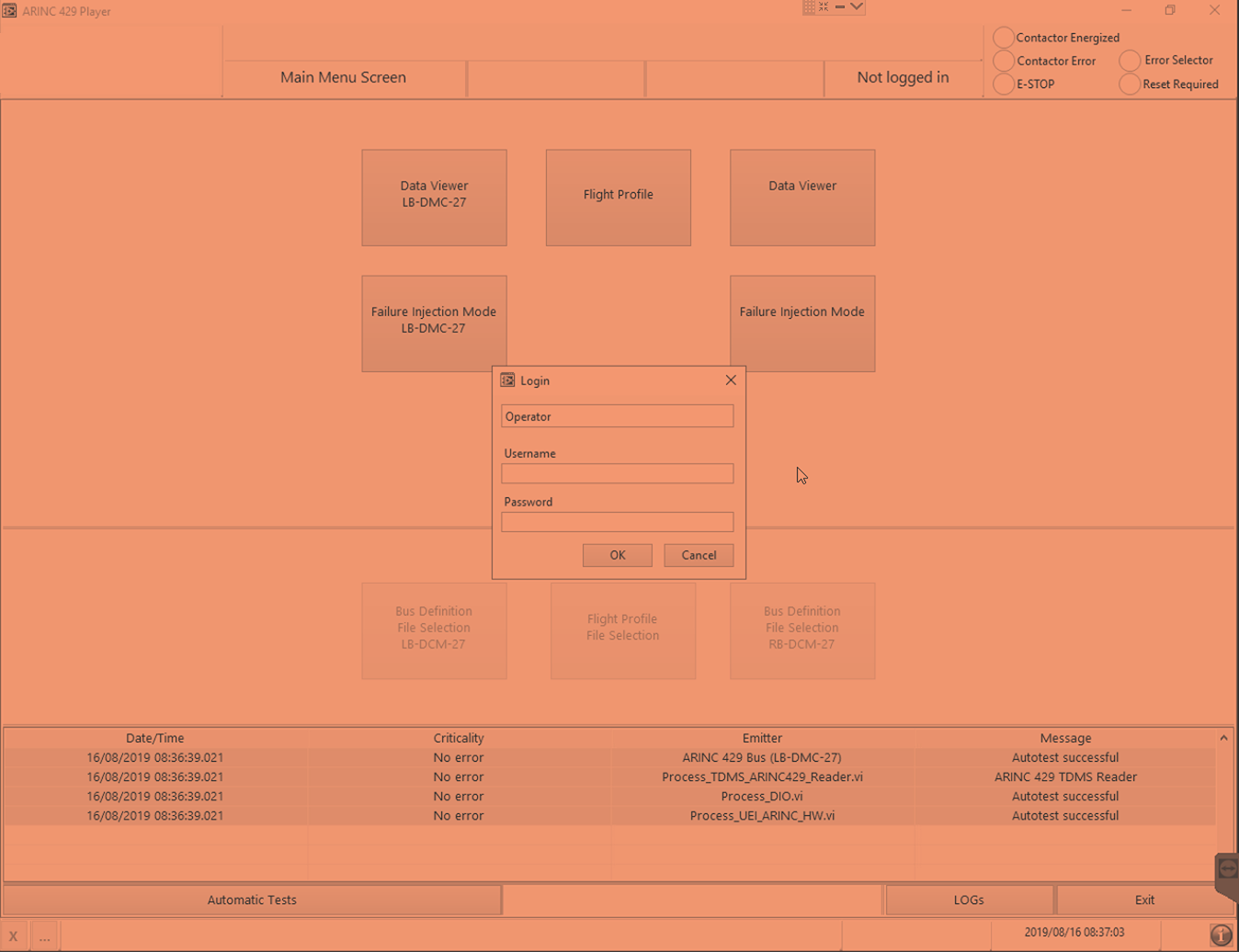

ARINC-429 Data Record and Playback System

ARINC-429 record and playback system that accurately captures and replays avionics data streams with precise time synchronization.

Includes fault injection and an intuitive LabVIEW interface to test, visualize, and validate onboard communications.

By choosing Neosoft for your custom software consulting and development needs, you benefit from recognized expertise, a personalized approach, and cutting-edge technologies to optimize your processes and ensure the quality of your products.

To discuss your specific needs, feel free to contact us.