The goal of the optical fiber inspection project is to detect defaults during manufacturing in order to mark it and not ship these out of specification fiber. The inspection is done using two cameras at 90 degrees apart. This application also detects concentricity errors (in percent) of the cladding and the coating of the optical fiber. The system consists of LabVIEW software with the NI Vision Development Module running on Windows and two cameras communicating by USB.

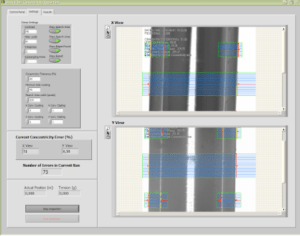

The system takes several frames per second and analyzes each frame to detect any concentricity defaults. Inspection is done according to the configuration parameters entered by the operator. Figure 1 shows the system user interface during an inspection.

Figure 1 – Optical Fiber Concentricity Inspection Interface

Every detected default is logged into a file and the fiber is marked using red spray paint so that is not shipped to the customer. The operator can easily go and check out every individual default at his convenience and eliminate the defective fiber if required when packaging the fiber. Statistics are also logged for every run in order to improve the process. This is very helpful to determine if there is a problem with the drawing tower in which the fiber is created.

Besoin d’informations complémentaires ?

Remplissez notre formulaire et l’un de nos experts vous recontactera au plus vite.

Site web développé par

Need more information?

Fill in our online contact form and one of our expert will contact you.

Website developed by