Machine Vision for real-time detection and correction of textile tissue misalignment

The goal of this project is to detect and correct any textile tissue misalignment in real-time during manufacturing. Misalignment detection involves capturing images of the fabric layers and then processes them to determine if the alignment is within the specification. Since the assembly line is very fast, the analysis algorithm had to keep their executing time to a minimum to keep up with the pace.

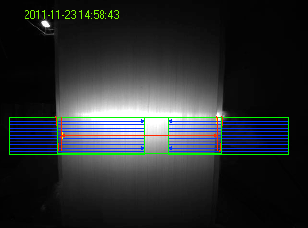

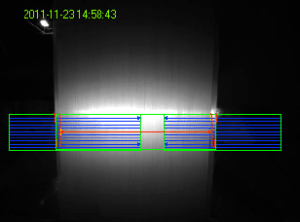

Figure 1 shows a typical image that needs to be analyzed by the machine vision system. The two fabric layers can be seen in the image. The system’s goal is to determine by what percentage they are misaligned to each other. A Region of Interest (ROI) is defined according to the brighter part of the image, in order to speed up the detection of the two textile layers.

Figure 1 – Example of alignment measurement

The visions algorithms are executed on a NI smart camera running the NI Real-Time operating system and thus, if rugged and able to keep up with the manufacturing pace. To stop or start the vision system, the user only has to plug into standard 120V AC outlet.

A remote user interface communicates with the NI Smart Camera using a TCP/IP link to give operators a way to see what is going on from the camera’s point of view.