Our system integration expert will reduce your overall risk and propose solutions that can meet and exceed your needs. Our expertise in software, electronic and mechanical design will allow you successfully complete your more complex system for an optimal solution that meets your unique requirements. Why settle for a generic solution when you can have a custom solution for similar price?

As project’s complexity increases, there is typically a need to integrate several technologies and/or sub-systems in order to get the optimal solution to meet unique requirements.

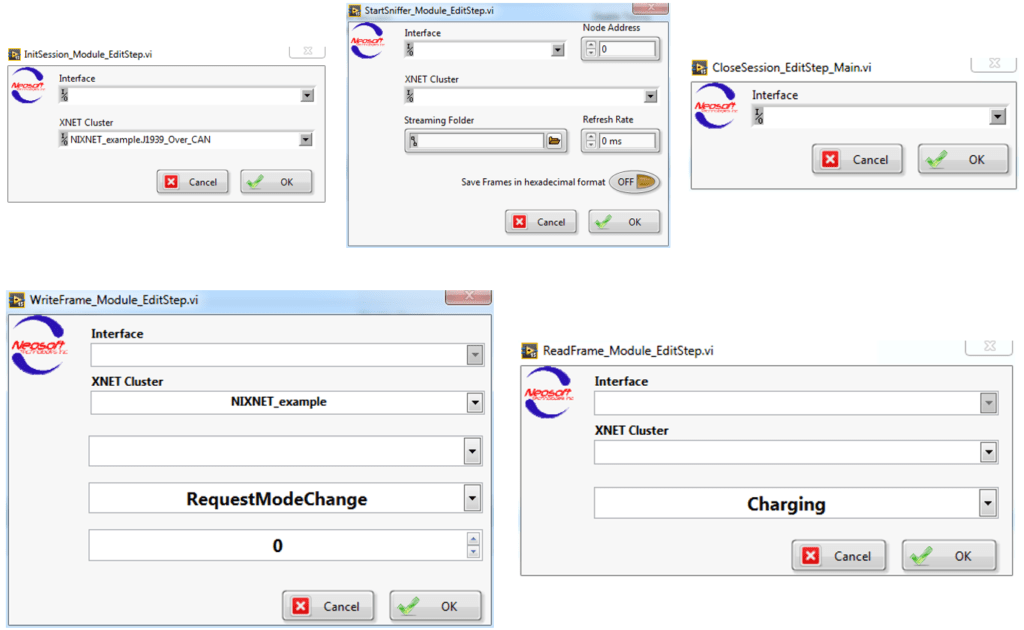

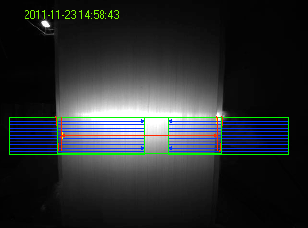

In some cases, the need is to optimize a current process already in place. So, we need to find out a way to integration the new solution into the current process. For example, adding an automated vision inspection system on your production line. That solution will typically need to communicate with the current setup in order to be efficient. Another example is the current system has limitation either in processing power, in acquisition speed or accuracy, etc.

In the end, we can provide several solutions to best meet your needs because of our technical expertise and experience. We can offer a complete solution from end-to-end including after delivery support and evolution.