WATS/SkyWATS from Virinco

Give a meaning to your test data : discover WATS solution !

Neosoft Technologies Inc. established a partnership with Virinco in order to help you address the management of your test data thanks to WATS software platform.

Neosoft Technologies Inc. established a partnership with Virinco in order to help you address the management of your test data thanks to WATS software platform.

It is then vital to have a solution to make the best use of the data collected during the production tests and on the repair stations in order to ensure the reliability of products quality. The analysis of these data makes it possible to give indicators quantifying the relevance of the tests, to ensure better traceability and to continuously optimize the production processes both internally and with external suppliers.

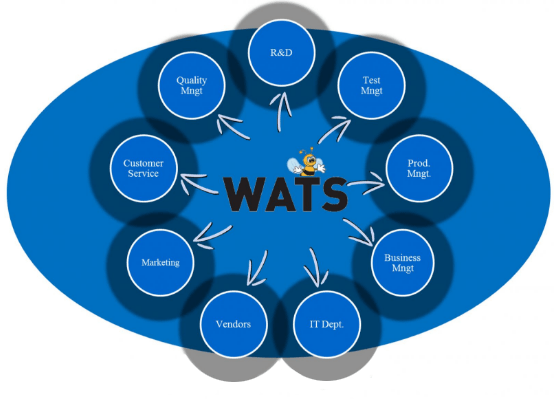

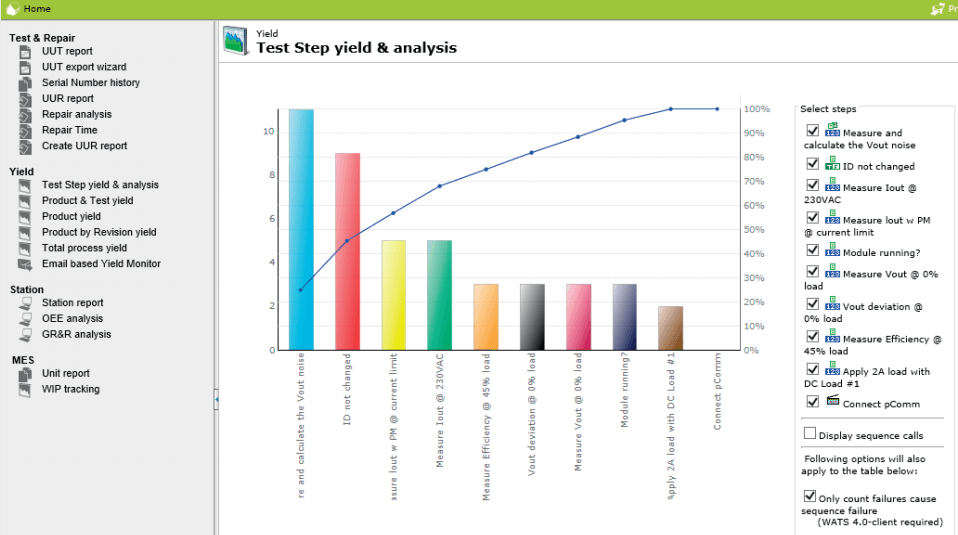

WATS solution makes it possible to use your existing test systems to analyze the data produced in order to calculate indicators quantifying the relevance of your measurements in production as well as the quality of the products under test. Thus, by presenting the data in a clear and intuitive way you can control and optimize your validation process of the units under test, detect drift quality and ensure traceability.

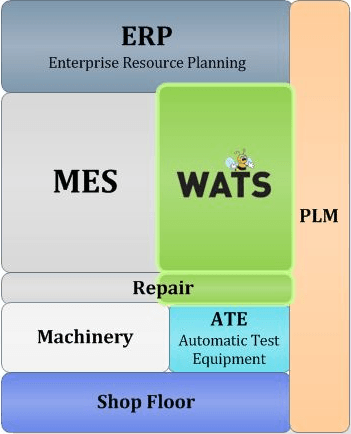

The WATS solution can be seen as a Manufacturing Execution System (MES), a system that manages manufacturing operations and test data in production. This platform enables the control and automation of the workflow, the distribution of test software as well as information on products and production.

WATS can be seen as a “plug in” for traditional MES, or as a stand-alone system to bridge the gap between an ERP and the test and manufacturing environment. The system consists of 4 main modules:

Whole system can be used through a powerful, reactive and customizable web interface.

The system for collecting and interpreting data can be hosted on a physical server at the customer floor or in the “cloud” (SkyWATS system). Depending on options selected and access rights, users of WATS solution can access:

Thus, if you choose the WATS solution, Neosoft Technologies Inc. can develop for you:

NI VeriStand is an open environment that offers a powerful solution for many application areas, from the rapid control prototyping, to the HIL tests or simpler real-time data logging applications. VeriStand is capable of executing custom LabVIEW plugins from most of its components: in the real-time engine (Custom Devices, models) or in the UI/workspace (Custom […]

National Instruments has not been a major actor in the field bus industry, but its rich platform and the versatility of the products are interesting when it comes to integrating such functionalities in a more global system (e.g. with data acquisition and/or visual inspection). Software-wise, the NI-XNET driver supports CAN (including CAN-FD and J1939), LIN […]

Le but de ce projet est de réaliser un système de détection de dépassement de seuil en temps réel permettant de calculer la durée de chaque étape d’un cycle de gravure à partir d’un signal échantillonné. Le logiciel est configurable pour une multitude de recettes de micro fabrication et permet de sauvegarder les résultats pour […]

By using LabVIEW and TestStand, we were able to build a generic librairy that would enable to read/write CAN message based on the SAE J1939 standard for our customer. This librairy was architected to interface with multiple UUTs at the same time with no effort. And finally, there was a utility to monitor all CAN […]

October 27th, 2017 Using the Report Generation Toolkit you might face a strange Error 97. This error might happen if the Microsoft Office version with which your LabVIEW code has been done came to change (new version installed on the computer or code/exe moved to a computer with a different version). Solving this problem is […]

The goal was to automate the alignment of the Fine Guidance Sensor of a telescope. The final system aligned several telescopes mounted in an aluminum structure that is required to withstand space conditions (in a near vacuum and at -250°C). One of the goals for this system was to find the exact position of each […]

The goal of the optical fiber inspection project is to detect defaults during manufacturing in order to mark it and not ship these out of specification fiber. The inspection is done using two cameras at 90 degrees apart. This application also detects concentricity errors (in percent) of the cladding and the coating of the optical […]

The goal of this project is to detect and correct any textile tissue misalignment in real-time during manufacturing. Misalignment detection involves capturing images of the fabric layers and then processes them to determine if the alignment is within the specification. Since the assembly line is very fast, the analysis algorithm had to keep their executing […]

April 4th 2017 Since April 8th 2014, Microsoft stoped supporting Windows XP officially. This means, no more update, not even security updates nor support. When looking into migrating your system, several aspects must be taken into consideration. National Instruments has a public document on the subject that is available at: http://www.ni.com/newsletter/52276/en/ In summary, you need: […]

April 18th 2017 For a majority of our projects, our customer and us are constantly face the dilemma of Build vs Buy. This is typically not a straightforward answer to a problem. In these cases, we’ll narrow down a couple of options and then do a quick financial model to determine, to the best of […]

Besoin d’informations complémentaires ?

Remplissez notre formulaire et l’un de nos experts vous recontactera au plus vite.

Site web développé par

Need more information?

Fill in our online contact form and one of our expert will contact you.

Website developed by